Instrument mouthpieces 3D-printed from corncob ‘plastic’

Advertisement

Hey there, time traveller!

This article was published 05/06/2020 (2019 days ago), so information in it may no longer be current.

Come this fall, beginner band students at Linden Meadows School will be using biodegradable, 3D-printed mouthpieces, thanks to a lot of ingenuity by teachers.

Virginia Helmer, the band educator at the Lindenwoods school and a music consultant for the Pembina Trails School Division, worked with David Gamble, a technology educator with the division, on the plan to ensure kids wouldn’t be sharing mouthpieces.

“We had to figure out how to run band classes for Grade 5 students, who get to try lots of instruments before they pick one to play,” Helmer said, adding they’re expecting 60 Grade 5 students in the fall. “But with the pandemic top-of-mind and provincial instructions on sanitizing items like mouthpieces, we needed to find a solution.”

An online search found that schools in the United States were turning to 3D-printed plastic mouthpieces for brass and woodwind instruments. A meeting at the division’s board office with Gamble proved to be fruitful when he told Helmer about the printer farm he had set up in the basement of the building on Henlow Boulevard.

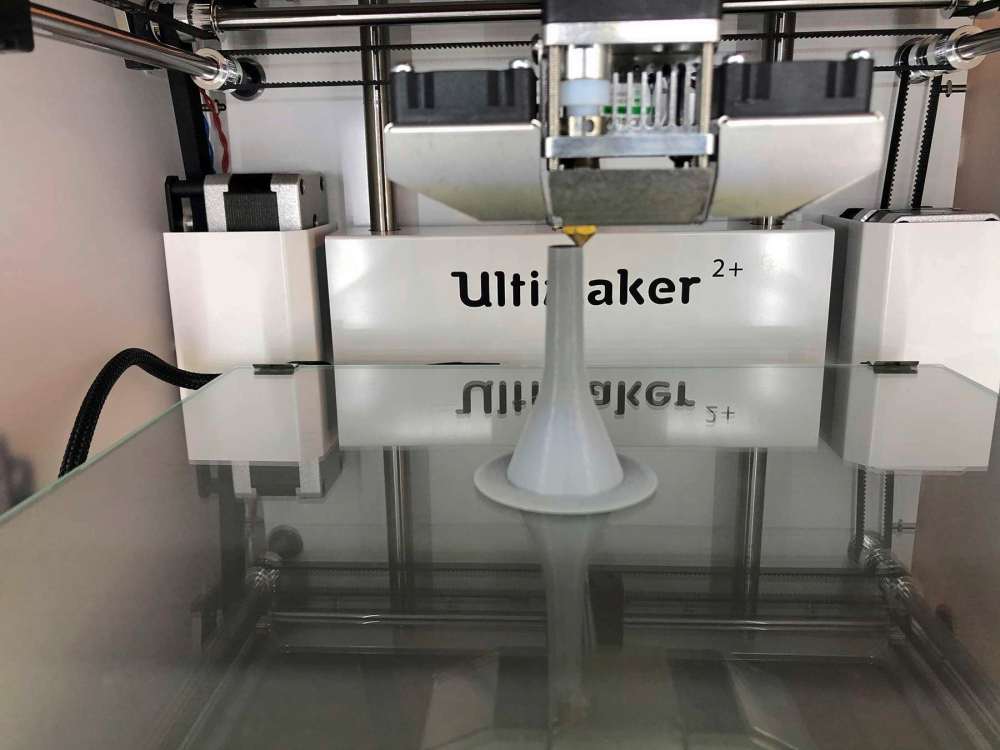

Gamble consolidated 12 3D printers, borrowed from technology programs at four division schools. He then found a source of biodegradable plastic to make the mouthpieces.

“I can print a single mouthpiece in 17 minutes,” he said. “By nesting them together, I can make up to 25 mouthpieces in 12 hours. Since I set the printers up to run overnight as well as during the day, I was able to turn out quite a few in a short period of time.”

While the mouthpieces will make their debut at Linden Meadows in the fall, Gamble expects all the band instructors in the division to jump on the bandwagon.

“I expect all 15 schools will want to use them. They can be made for about 20 cents per mouthpiece. This includes the ligatures for instruments like clarinet and saxophones, which need a reed inserted inside. I’m calculating we need 200 to 300 trumpet mouthpieces, for example,” Gamble said, adding this outside-the-box thinking is what he teaches in STEM labs at division schools.

Grade 5 students at Linden Meadows will only be using the mouthpieces, not the whole instruments, she added. The mouthpieces can be sterilized in a dishwasher, and each student will keep the ones they try. Once they settle on a favourite, the students then rent or purchase their own instrument.

“People have different facial characteristics that help us match an instrument to them. For example, a student with a sweetheart-shaped mouth might find it hard to play a flute,” Helmer said, adding that while she can play a trumpet, her mouth isn’t big enough to play a tuba with its bigger mouthpiece.

Helmer moved band practices outside, setting up a hand sanitizer station, and ensuring students only touch their assigned chair and music stand, which are also sanitized. She teaches each band class outside at the school on separate afternoons and is continuing to teach online in the mornings.

“Trying to teach band online wasn’t working. There’s a lag on the (Microsoft) Teams video, so it was hard to hear individual students,” she said. “When we get together outside, I can play music and the students can play it back at me all at once. They get so much more out of this.”

She’s tried the plastic mouthpiece on her trumpet and found it works quite well. “David did a really good job on these,” she said. “I’m also really happy that they’re made of corn cobs, so sooner or later, they will biodegrade.”