Innovation, precision, efficiency Eascan Automation thrives on challenge, support of custom-built machines for manufacturing sector

Read this article for free:

or

Already have an account? Log in here »

To continue reading, please subscribe:

Monthly Digital Subscription

$1 per week for 24 weeks*

- Enjoy unlimited reading on winnipegfreepress.com

- Read the E-Edition, our digital replica newspaper

- Access News Break, our award-winning app

- Play interactive puzzles

*Billed as $4.00 plus GST every four weeks. After 24 weeks, price increases to the regular rate of $19.95 plus GST every four weeks. Offer available to new and qualified returning subscribers only. Cancel any time.

Monthly Digital Subscription

$4.99/week*

- Enjoy unlimited reading on winnipegfreepress.com

- Read the E-Edition, our digital replica newspaper

- Access News Break, our award-winning app

- Play interactive puzzles

*Billed as $19.95 plus GST every four weeks. Cancel any time.

To continue reading, please subscribe:

Add Free Press access to your Brandon Sun subscription for only an additional

$1 for the first 4 weeks*

*Your next subscription payment will increase by $1.00 and you will be charged $16.99 plus GST for four weeks. After four weeks, your payment will increase to $23.99 plus GST every four weeks.

Read unlimited articles for free today:

or

Already have an account? Log in here »

Hey there, time traveller!

This article was published 17/01/2025 (405 days ago), so information in it may no longer be current.

When he was a teenager feeling a need for more speed than his bicycle could offer, Phil Bernardin could have saved up and bought a moped. Instead, he took a chainsaw engine and turned his bike into a motorcycle.

He drew the initial plans on a napkin and headed to the library to read about engines. He figured out the gear ratio he needed and created a motorized vehicle that could travel 50 km/h at top speed.

Suddenly, getting to his part-time job at McDonald’s was a lot more fun.

MIKE DEAL / FREE PRESS

Phil Bernardin, co-owner of Eascan Automation. The Winnipeg company started in 1992, and designs, builds, commissions and services fully integrated industrial robots and custom machines. It currently has a staff of more than 50.

“I’ve always been kind of mechanically curious,” Bernardin says. “I just love the physical world and seeing how it operates and being part of that.”

That curiosity, love for building and desire to try new things serves Bernardin well today in his role as president and chief technology officer at Eascan Automation Inc.

Headquartered on Wall Street, the Winnipeg company specializes in providing turnkey automation solutions for businesses in manufacturing. The company’s passion for motion control systems drives staff members to integrate the latest technologies into their designs, ensuring machines created by Eascan are as efficient and effective as possible.

Spend some time on Eascan’s YouTube page and you’ll see a variety of machines the company has created. These include robots and “cobots” — collaborative robots built to work alongside people, equipped with sensors that shut the equipment down the moment it comes into contact with a human.

There’s the state-of-the-art machine built for bakeries and food manufacturing operations that de-pans muffins and cupcakes 72 at a time. There’s the cobot for chemical and food manufacturers that picks up five empty jugs from a pallet and places them on an assembly line so they can be filled.

There’s also the automatic drum and tote filler machine, which includes a vision system that precisely manages the filling of containers while improving cycle times, enhances staff safety by limiting their exposure to chemicals and delivers precise product net weight, so companies don’t have to worry about under- or over-filling.

There’s even a robotic curling rock-thrower Eascan invented for the Cargill Curling Training Centre in Morris — a one-of-a-kind teaching tool that helps curlers train and improve their skills.

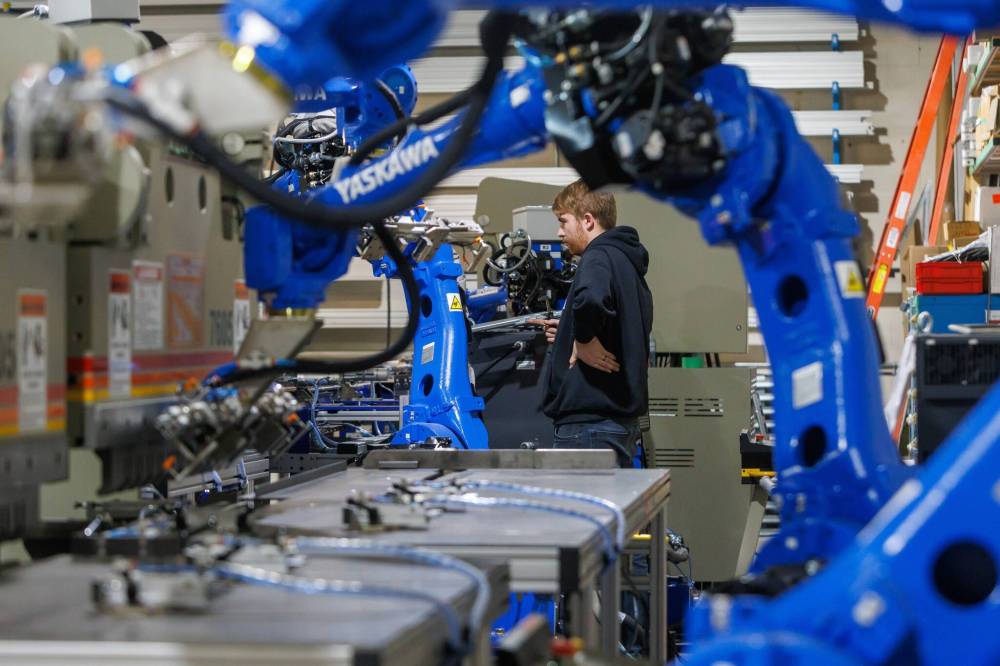

MIKE DEAL / FREE PRESS

Joel Vanderveen, mechanical engineering technologist, programs a robot.

Innovation, precision and efficiency are the priorities at Eascan; it’s all part of the company’s goal to improve productivity, efficiency and safety for customers.

And it all starts with a problem.

A customer doesn’t know how to fix something in their facility or they want a process to go faster or they want to increase the quality of their product or improve safety. An Eascan employee visits the facility, troubleshoots the problem and starts brainstorming solutions.

Eascan employees then design, build and program the machine at either the 12,000-square-foot head office on Wall Street or the company’s second facility, an 8,000-sq.-ft. space on Warman Road.

Eascan has base models for certain types of machines, but everything gets tailored to each customer’s specific needs.

Once the machine is up and running, the customer inspects it to make sure it meets their requirements. When the customer signs off, Eascan disassembles the machine, ships it to the customer, reassembles it and commissions it.

Being on call in case something ever goes wrong is a key part of Eascan’s offerings and something the company views as one of its advantages: if you’re a Manitoba business and you hire Eascan, you can be sure Bernardin’s team will be close by for future assistance.

“The first half of the project is making the machine,” he says. “The next half of the project is supporting it and making sure it runs effectively over the next 10 years.”

MIKE DEAL / FREE PRESS

Ryan Bryson, electrical technician, works on a panel assembly.

Eascan was founded in 1992 by Jake Bergsma. In May 2001, Bernardin had just returned to Winnipeg after completing a degree in mechanical engineering at the University of Waterloo when Bergsma hired him to be the company’s first employee. At the time, the company operated out of an 800-sq.-ft. garage and annual sales were $500,000.

Eventually, Bernardin became a co-owner and the two partners grew the company together. Bernardin bought Bergsma out in 2017. Five years later, Bernardin sold half of the business to Future Transfer, a distribution company.

In 2020, Eascan employed 22 people and brought in $3 million annually. Today, there are more than 50 people on staff — many of them graduates from the University of Manitoba and Red River College Polytechnic — and annual sales are around $9 million.

Meeting customers’ needs and working with great employees are the two things Bernardin most enjoys about his work.

“A lot of times, the types of people that we employ are very similar to me as well — they like the challenge,” says Bernardin, who is also part of the ownership group at Torque Brewing in Winnipeg.

If you’re looking for a job that’s formulaic, he adds, Eascan is not for you.

“This is the place where you go to be challenged,” he says. “You’re always bouncing around. So it’s not very predictable, but it sure is rewarding.”

The work Eascan does demands employees keep up with the latest technology and it’s something clients expect, too. To that end, the company is starting to look into artificial intelligence.

MIKE DEAL / FREE PRESS

David Petrie, Electrical Engineer at Eascan Automation looking at a control schematic.

Bernardin foresees a time when Eascan’s design work is produced by AI: someone takes pictures and videos of the application and uploads them to a computer, inputs the scope of work and the computer creates the plan and instructs employees on how to execute it.

“Essentially, (we would be) automating our jobs,” he says. “(It’s) kind of weird to think about, but that to me is where things are really going.”

No matter what the design process looks like in the future, Bernardin is proud to lead a Winnipeg company focused on serving customers in the keystone province.

“We are advancing automation in Manitoba … and going home knowing that everyone’s going to be a little bit more efficient, a little bit safer, a little bit more productive,” he says. “Knowing that we’re contributing to that advancement, to me, is very rewarding.”

aaron.epp@freepress.mb.ca

Aaron Epp reports on business for the Free Press. After freelancing for the paper for a decade, he joined the staff full-time in 2024. Read more about Aaron.

Every piece of reporting Aaron produces is reviewed by an editing team before it is posted online or published in print — part of the Free Press‘s tradition, since 1872, of producing reliable independent journalism. Read more about Free Press’s history and mandate, and learn how our newsroom operates.

Our newsroom depends on a growing audience of readers to power our journalism. If you are not a paid reader, please consider becoming a subscriber.

Our newsroom depends on its audience of readers to power our journalism. Thank you for your support.