Strength in versatility ‘I don’t have to be one brand. That’s the best’: GarmaTech Inc. makes everything from workwear to bridal gowns

Read this article for free:

or

Already have an account? Log in here »

To continue reading, please subscribe:

Monthly Digital Subscription

$1 per week for 24 weeks*

- Enjoy unlimited reading on winnipegfreepress.com

- Read the E-Edition, our digital replica newspaper

- Access News Break, our award-winning app

- Play interactive puzzles

*Billed as $4.00 plus GST every four weeks. After 24 weeks, price increases to the regular rate of $19.95 plus GST every four weeks. Offer available to new and qualified returning subscribers only. Cancel any time.

Monthly Digital Subscription

$4.99/week*

- Enjoy unlimited reading on winnipegfreepress.com

- Read the E-Edition, our digital replica newspaper

- Access News Break, our award-winning app

- Play interactive puzzles

*Billed as $19.95 plus GST every four weeks. Cancel any time.

To continue reading, please subscribe:

Add Free Press access to your Brandon Sun subscription for only an additional

$1 for the first 4 weeks*

*Your next subscription payment will increase by $1.00 and you will be charged $16.99 plus GST for four weeks. After four weeks, your payment will increase to $23.99 plus GST every four weeks.

Read unlimited articles for free today:

or

Already have an account? Log in here »

Hey there, time traveller!

This article was published 24/04/2025 (307 days ago), so information in it may no longer be current.

Shelley Ediger recalls being five years old, standing in her family’s home on a grain farm in rural Manitoba and imagining herself wearing a beautiful dress of her own design.

Ediger was already proficient with her mother’s white Bernina sewing machine. She cut a rectangular piece off a bolt of fabric, tied it around her neck and envisioned the possibilities.

“I still remember looking in the mirror and thinking, ‘Someday I could be a fancy lady wearing this gown,’” recalls Ediger, who grew up in Homewood, some 75 kilometres southwest of Winnipeg. “‘I could make the dresses that I see in magazines.’”

MIKAELA MACKENZIE / FREE PRESS

GarmaTech founder Shelley Ediger at the Winnipeg company’s manufacturing shop in the Exchange District.

Today, Ediger gets to make everything from workwear to bridal gowns with GarmaTech Inc., the company she started in 2018.

Headquartered in a 1,000-square-foot production space in the Exchange District of Winnipeg, Ediger and her seven employees do design work, pattern making and manufacturing for a range of brands. Six local contractors help out when things are busy and the company has partners in China, Vietnam and South Africa.

It’s a nimble, efficient operation that has handled orders ranging from 100 to 20,000 units.

Now 37, Ediger enjoys that every day is different. “I don’t have to be one brand. That’s the best.”

Growing up, Ediger had trouble finding clothes that fit so she made her own.

“I’ve always been known for changing my clothes 15 times a day,” says Ediger, who made five different dresses to wear throughout her wedding day. “Gotta get the look right for the weather, for the outing — whatever it’s gonna be.”

Ediger earned a certificate in small-business management at Red River College Polytechnic before moving to Vancouver to study fashion design at the Blanche Macdonald Centre.

In 2012, she launched Dediger, a menswear brand she ran on the side while working as a patternmaker at Peerless Garments. In 2018, with the encouragement of Peerless CEO and co-owner Albert El Tassi, she struck out on her own and started GarmaTech. Around that same time, she wound down Dediger.

MIKAELA MACKENZIE / FREE PRESS

In recent months Ediger brought her husband, Bobby Wall (left), on board to work as sales director.

Ediger bears a scar on the knuckle of her right index finger from an important day in GarmaTech’s history.

It was soon after she had started the company, which at that time was based in a 300-sq.-ft. second-floor studio on Pacific Avenue. Ediger got a contract that necessitated a buttonhole machine — a $2,500 piece of equipment — and she could not find a used one in Winnipeg.

She was about to purchase an expensive used machine from Toronto when she decided to check online sales platform Kijiji one more time. A local listing popped up offering a buttonhole machine for $200.

Two messages to the seller went unanswered, so Ediger decided to find them by driving up and down every street in the postal code attached to the listing and visiting any business that looked like it might have the machine in question.

Eventually, she stopped at a Portage Avenue bridal shop. Not only was it the right place, but the shop was going out of business and the seller offered her numerous other pieces of manufacturing equipment. It was all priced to go, with the stipulation she remove it from the premises that day.

With the help of her father and some movers she found online, Ediger moved the equipment onto a flatbed truck during a rainstorm.

At some point, she cut herself.

“I have this giant scar because I wasn’t paying attention to what I was doing. I was just moving and then, all of a sudden, there’s blood pumping out of my hand.”

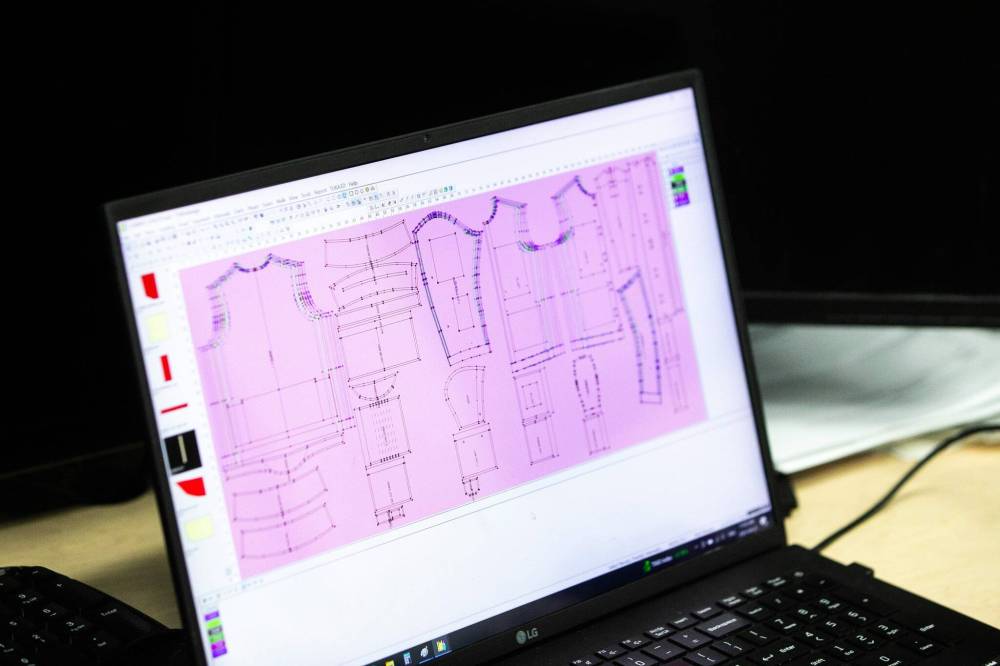

MIKAELA MACKENZIE / FREE PRESS

Digital patterns are displayed on a work laptop.

Locating the machine she needed and obtaining equipment she wasn’t expecting, finding movers on short notice — everything aligned in a way that told Ediger she was on the right path.

The additional equipment meant she needed to find a bigger space, which led her to GarmaTech’s current location (61 Juno St.), which she rents from El Tassi.

The company has never been short of work, Ediger says, but in recent months she’s brought her husband, Bobby Wall, on board to work as sales director.

Wall’s first order of business was to promote Sero, a line of do-it-yourself sewing kits Ediger created to encourage people to make their own clothing. GarmaTech makes the kits using leftover fabric.

Wall, who also works in real estate, says he’s amused when he encounters Winnipeggers who don’t realize companies like GarmaTech exist in their city.

“They’re like, ‘Oh, I had no idea you could actually manufacture garments here,’” the 43-year-old says. “They’re just blown away.”

He notes Winnipeg has a long history of garment manufacturing. The industry employed thousands of people in the city before manufacturers moved abroad to find cheaper labour.

MIKAELA MACKENZIE / FREE PRESS

Inderjit Jassal cuts fabric at GarmaTech. Ediger and her seven employees do design work, pattern making and manufacturing for a range of brands.

Lately, Wall has been spreading the word to Manitoba businesses that if they need to have clothing manufactured, they can do it in Winnipeg. With the U.S.-Canada trade war and a recent emphasis on buying local, it’s an opportune time for that message.

“Let’s make things in Canada,” Ediger says. “We can and it’s so easy.”

Working with a Canadian business is important to & For Love, a Toronto-based bridal company that has outsourced work to GarmaTech since 2021.

“Shelley is super professional; she knows what she’s doing,” says co-founder Angel Spendlove. “We just really wanted to keep our company Canadian-based, so finding Shelley was great.”

For Nicola Loewen, owner of Mad About Style on Academy Road, working with GarmaTech has allowed her to create a clothing line unique to her boutique.

Since 2020, Loewen and her colleagues have worked with Ediger to design the Mad Collection, which GarmaTech manufactures.

“It made sense to work with another local, female-owned business,” Loewen says. “Shelley really pours her heart into each project that she’s working on. From the beginning, she’s understood our brand and what we’re trying to achieve. She just gets it done.”

After years of designing and manufacturing for other people, Ediger recently took the time to create the garment she envisioned when she stood in front of the mirror with a piece of fabric slung over her shoulders more than 30 years ago.

MIKAELA MACKENZIE / FREE PRESS

Susan Crouise sews at GarmaTech’s 1,000-sq.-ft. production space.

It’s a bias cut halter dress with an open back that will be available via Sero in the coming months.

After years of building GarmaTech at a slow and steady pace, Ediger feels good about the foundation she’s laid.

“We are strong, we are capable and now we are ready and we are solid,” she says. “I feel confident now that we’re ready to do almost anything.”

aaron.epp@freepress.mb.ca

Aaron Epp reports on business for the Free Press. After freelancing for the paper for a decade, he joined the staff full-time in 2024. Read more about Aaron.

Every piece of reporting Aaron produces is reviewed by an editing team before it is posted online or published in print — part of the Free Press‘s tradition, since 1872, of producing reliable independent journalism. Read more about Free Press’s history and mandate, and learn how our newsroom operates.

Our newsroom depends on a growing audience of readers to power our journalism. If you are not a paid reader, please consider becoming a subscriber.

Our newsroom depends on its audience of readers to power our journalism. Thank you for your support.