From tiny seeds grow…

BrettYoung builds capacity, efficiency in new $20-M south Winnipeg cleaning, sorting, packaging facility

Advertisement

Read this article for free:

or

Already have an account? Log in here »

To continue reading, please subscribe:

Monthly Digital Subscription

$1 per week for 24 weeks*

- Enjoy unlimited reading on winnipegfreepress.com

- Read the E-Edition, our digital replica newspaper

- Access News Break, our award-winning app

- Play interactive puzzles

*Billed as $4.00 plus GST every four weeks. After 24 weeks, price increases to the regular rate of $19.95 plus GST every four weeks. Offer available to new and qualified returning subscribers only. Cancel any time.

Monthly Digital Subscription

$4.99/week*

- Enjoy unlimited reading on winnipegfreepress.com

- Read the E-Edition, our digital replica newspaper

- Access News Break, our award-winning app

- Play interactive puzzles

*Billed as $19.95 plus GST every four weeks. Cancel any time.

To continue reading, please subscribe:

Add Free Press access to your Brandon Sun subscription for only an additional

$1 for the first 4 weeks*

*Your next subscription payment will increase by $1.00 and you will be charged $16.99 plus GST for four weeks. After four weeks, your payment will increase to $23.99 plus GST every four weeks.

Read unlimited articles for free today:

or

Already have an account? Log in here »

Hey there, time traveller!

This article was published 20/03/2024 (678 days ago), so information in it may no longer be current.

When you spread a bag of Scotts Turf Builder on your lawn or marvel at the lushness of the fairway at your favourite golf course this spring, it’s likely the grass seed involved was processed, bagged and shipped at BrettYoung’s sprawling operation west of the Brady Road landfill.

The Winnipeg company — founded by Bill Brett and Reg Young — has been in the turf and forage seed business since the 1950s, and has become the largest player in the field in Canada.

To do that has meant a lot of expansion at its 30-acre site.

MIKE DEAL / WINNIPEG FREE PRESS

BrettYoung COO, Cory Baseraba, with a small box of cleaned seed that is kept during the quality control process.

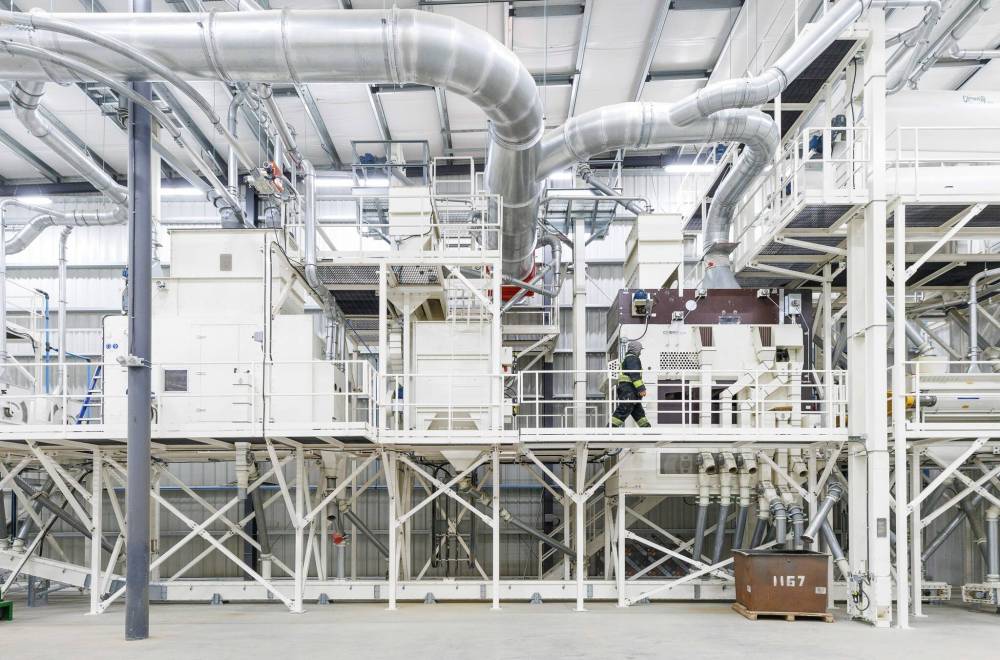

Six new buildings have been constructed on the site in the last 10 years — the most recent of which is a $20-million, 60,000-square-foot cleaning, sorting and packaging facility featuring automated technologies that will allow for three times the capacity of its existing production lines, the company says.

Erik Dyck, who became BrettYoung CEO in September and is co-owner of the company, along with his father, Lloyd, said the new facility is the largest and most complex of its kind in Canada. (Dyck’s grandfather bought the company in the mid-1970s.)

Although it processes and markets a few dozen different kinds of seeds, its turf seed business is its largest (which the new facility will exclusively handle).

“We’re the largest primary processor and producer of forage and turf seed in Canada,” Dyck said. “This new investment allows us to bring a diverse range of options to farmers, like forage and turf species that provide all sorts of agronomic benefits, allowing farmers to diversify crop rotations and add to soil carbon.”

The recent investment is a testimony to the company’s attention to quality and customer service, according to its leadership.

“We’ve had 12 to 15 years of steadily increasing sales and volumes through this facility,” said Cory Baseraba, chief operating officer. “As our customers have wanted more and more from us, the (Dyck) family has been more than willing to invest.”

Including the new, so-called North Core turf seed processing facility, the company has doubled its production footprint in the last 10 years.

The new line includes a computer-controlled pneumatic air conveyor system, with 36 diverting valves that move seeds around the facility where it they are cleaned, blended and packaged with minimal labour required.

“In our old processing plant there are 25 forklift trucks moving bins around,” said Baseraba. “There’s a few forklifts required in North Core but the efficiency gains are huge.”

MIKE DEAL / WINNIPEG FREE PRESS

BrettYoung’s new $20 million seed cleaning and packaging facility just off the South Perimeter Highway west of the Brady landfill.

North Core — commissioned about a year ago — requires fewer than 10 people to operate.

The company employs a total of about 250, with about 140 of them at the Winnipeg complex and the rest split between two Alberta and one Ontario processing and distribution operations.

BrettYoung contracts with farmers, mostly in Western Canada, as well as some international, to produce 30-40 different types of highly specialized turf seed, a range of forage crops, as well as some specialized canola and soybean seeds.

The company also does a big business in forage seeds, servicing reclamation sites for the oil and gas, mining and municipal sectors, offering native grasses, alfalfa and clover to regreen spaces.

BrettYoung markets more than 25 varieties of perennial rye grass seeds alone.

A partnership with German-owned DL Seeds — whose North American operation is based in Morden, Man., with a satellite facility at BrettYoung’s south Winnipeg operation — is responsible for its line of specialized canola seeds.

This week, the company is awaiting a shipment of 38 containers of hybrid canola seed from Chile, which is grown in the winter and then shipped to Winnipeg to be ready for spring planting on the Prairies.

Its wholesale forage and turf business exports to more than 40 countries, with the U.S. and China being the largest destination.

The $200-million per year company had a significant spike in business during the COVID-19 pandemic when public activity options were limited but yard improvement and golfing were still on the table. (Sales in 2023 took a dip with pandemic regulations in the rear-view mirror.)

Meantime, Dyck said he holds to his father’s mantra — “If you’re not growing than you’re going.” He said the new Winnipeg facility will help manage the seasonal spikes in demand.

MIKE DEAL / WINNIPEG FREE PRESS

BrettYoung CEO, Erik Dyck (right) and COO, Cory Baseraba (left).

“Farmers only harvest one time per year in North America,” said Baseraba. “In order for us to grow, we have to get our hands on all of it at harvest time.”

Then there is cool-season grass seeds used for over-seeding golf courses in the southern U.S. that need to be planted in the fall.

“We only have three-to-four weeks to do that,” the COO said. “To handle that we need horsepower to push it through quick.”

The Chinese market kicks in with overseas shipments usually during the winter months.

The winter months are also occupied with bagging and packaging that fills more than 100,000 sq. ft. of warehouse space at its complex, with pallets of perennial rye grass, tall fescue, fine fescue and Kentucky Bluegrass waiting to get pushed out for spring planting.

“We can never have enough warehousing space,” said Dyck.

martin.cash@freepress.mb.ca

History

Updated on Thursday, March 21, 2024 2:12 PM CDT: Clarifies location and production of DL Seeds