Ramping up Canada’s bang for the buck

Advertisement

Read this article for free:

or

Already have an account? Log in here »

To continue reading, please subscribe:

Monthly Digital Subscription

$1 per week for 24 weeks*

- Enjoy unlimited reading on winnipegfreepress.com

- Read the E-Edition, our digital replica newspaper

- Access News Break, our award-winning app

- Play interactive puzzles

*Billed as $4.00 plus GST every four weeks. After 24 weeks, price increases to the regular rate of $19.00 plus GST every four weeks. Offer available to new and qualified returning subscribers only. Cancel any time.

Monthly Digital Subscription

$4.75/week*

- Enjoy unlimited reading on winnipegfreepress.com

- Read the E-Edition, our digital replica newspaper

- Access News Break, our award-winning app

- Play interactive puzzles

*Billed as $19 plus GST every four weeks. Cancel any time.

To continue reading, please subscribe:

Add Free Press access to your Brandon Sun subscription for only an additional

$1 for the first 4 weeks*

*Your next subscription payment will increase by $1.00 and you will be charged $16.99 plus GST for four weeks. After four weeks, your payment will increase to $23.99 plus GST every four weeks.

Read unlimited articles for free today:

or

Already have an account? Log in here »

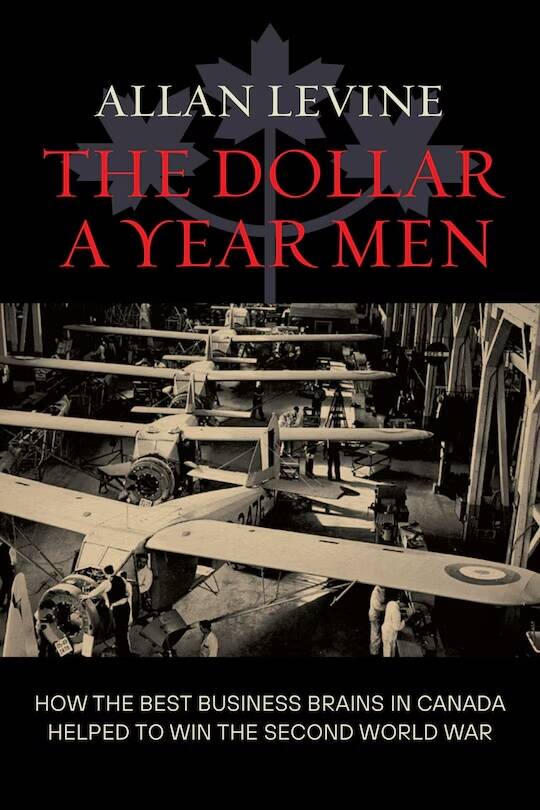

During the Second World War, hundreds of Canadian businessmen volunteered their services to lead Canada’s wartime economy. They were known as “dollar-a-year” men, though the vast majority were not actually paid a dollar each year. They played a significant role in transforming Canada into the fourth-largest industrial power in the world. In this adapted excerpt from The Dollar a Year Men: How the Best Business Brains in Canada Helped to Win the Second World War by Allan Levine, the story of Canada’s wartime aircraft industry is chronicled.

IN MID-JUNE 1940, Halifax businessman Ralph Pickard Bell was on a fishing trip in Prince Edward Island when he received a telegram from C.D. Howe. The all-powerful minister of the Department of Munitions and Supply in the Liberal government of William Lyon Mackenzie King requested that Bell travel to Ottawa immediately to meet with him. Bell replied that he was on vacation and could not leave. Howe expressed his displeasure. Upon further reflection, Bell, who no doubt had been following the news stories about the Nazi conquest of Western Europe, reconsidered. He chartered a private plane and was in Howe’s office the next day. “That’s better,” said Howe with a smile when he saw him.

Howe had first met Bell and his wife, Anna (called Rita), on a cruise to Bermuda in the late 1920s and knew that Bell was an amateur pilot. He told Bell that he wanted him to oversee Canada’s new aircraft production program. Bell was taken aback. He said he could fly planes, not build them. “I didn’t ask you that,” Howe barked. “I said I wanted you to take charge.” By the time the meeting ended, Bell had been appointed the director general of the aircraft production branch, a position he was to hold until October 1944.

National Film Board of Canada / Library and Archives Canada

C.D. Howe gets the feel of things by taking hold of a steering wheel during ceremonies on June 19, 1943, that marked the delivery of the half-millionth unit of motorized equipment produced in Canada during the Second World War.

Few dollar-a-year men personified a Munitions and Supply branch like Ralph Bell. For more than four years, he was at the centre of a remarkable and complex undertaking: the development of Canada’s wartime aircraft industry almost from scratch. In 1939, there were eight small aircraft plants that employed approximately 4,000 workers and produced about 40 airplanes a year in a total of 500,000 square feet of factory space. These factories were poorly equipped, and most were located close to desolate fields. They were supported by a handful of service, repair and overhaul shops in Montreal, Toronto and Winnipeg. By 1944, the industry employed more than 116,000 people — 30,000 of whom were women who worked as seamstresses, riveters and welders. They manufactured more than 4,000 planes annually in 15 million square feet of factory space. In all, more than 16,000 aircraft — Lancaster bombers, Avro Ansons, De Havilland Mosquitos, Boeing’s huge Catalina flying boat, the Curtiss Helldiver, and the Harvard and Cornell trainers, among others — were produced during the war to service the RCAF, the British Commonwealth Air Training Plan (especially the Avro Ansons), and the air forces of Britain and the United States. The estimated total value of this production was $850 million — the equivalent of about $14 billion today.

This was no easy task. Bell, a strong-minded Halifax businessman and entrepreneur, had to deal with a myriad of personalities and problems. He threatened to resign at least once when he profoundly disagreed with the initial charter for Federal Aircraft Limited, a Crown corporation — Howe tore up his resignation letter — and he pressed on. Bell was diligent and dedicated, and knew instinctively what the job he was given required.

Some of the headaches he endured and clashes he was involved in were caused in part by his foul and explosive temper. As a businessman, Bell was prone to using profanity and could be downright nasty, especially to his employees. “He turned out to be the most difficult man to work with that any of us had ever experienced,” said Hal Connor, who worked closely with Bell after the war during his time as the first president of National Sea Products in Halifax. “When he was nice, he was so nice you were prostrated with his generosity and his kindness and thoughtfulness. But when he was bad, he was terrible. He made people cringe, even cry. I have seen women who worked for him burst into tears. He was given to the most awful rages of anybody I’ve ever known.”

As CEO of aircraft production during the war, Bell believed that he could only truly succeed if he had the “authority to make decisions and power to have them carried out,” as he explained to the Financial Post’s Floyd Chalmers in a private conversation over dinner in mid-December 1940. Two days later, the editor attacked Howe for leaving his dollar-a-year business managers “with no more authority than office boys,” adding that, “production of the munitions of war is an industrial job and it should be entrusted to industrialists.”

During the first year Bell was in Ottawa, he indeed became frustrated and felt that he had a “glorified title” as director of aircraft production. That frustration was rooted in what he regarded as the indecisiveness of British and Canadian air force officials over precisely what they wanted. “It takes them months to decide on the simplest matter,” he told Chalmers, “and when the decision is made they are apt to reverse it the next day.”

One example of an exasperating situation Bell and the industry had to deal with involved the production of Mk. II Lysanders, a single-engine army co-operation aircraft, mainly used for reconnaissance and training. When the war broke out the British air ministry placed a large order for the planes with National Steel Car Corporation. The Hamilton-based company was known as a manufacturer of railway rolling stock, though its plant in Malton (near Toronto) was used for aircraft production. In order to accommodate the British contract, the company expanded its Malton factory. Work proceeded through the first six months of 1940, but in June — when much of Western Europe, including France, was occupied by Germany — the British halted their order, causing serious problems for National Steel. The contract was completed: The British took some of the planes, the RCAF got 92, and National Steel Car’s extra plant space was used for the production of Avro Anson trainers. For Bell, however, this aggravating episode represented a typical display of British indifference to the hard work undertaken by Canadians during the war.

As for his authority, Bell fully appreciated that he answered to Howe and respected the minister, even if they frequently bickered. “Howe was not one to bear a grudge,” recalled lawyer and former dollar-a-year man Frank Covert in a 1976 interview. Once Howe and Bell had an argument, Covert continued, “Bell showed his feelings by refusing to speak to Howe … (who) hoped Bell wouldn’t go on with it; after all, he had the advantage in being able to speak to the House of Commons.” Eventually, Bell got over it. At the same time, Bell was highly respected by the Canadian aircraft manufacturing industry, which bemoaned the fact that his decisions were often countermanded by Howe.

On June 20, 1940, a day after Bell’s official appointment as director general of the aircraft production branch, an emergency meeting was convened in Howe’s office. In attendance were Bell and other representatives from Munitions and Supply as well as officials from the Department of Defence. As “strange as it may seem in retrospect,” Jack de N. Kennedy (who wrote a history of munitions and supply in 1950) later noted, aircraft orders still had to be arranged, and that was not to happen for another six-and-a-half months. Even in early December 1940 — on the night of December 29, the Luftwaffe dropped incendiary bombs on London’s financial district starting what was called “the Second Great Fire of London” — it was the view of Phil Garrett, the managing director of De Havilland Aircraft of Canada, that the British Air Ministry and the Society of British Aircraft Constructors “do not want an aircraft industry established in Canada,” as he told Chalmers.

Bell had the same opinion, also telling Chalmers a short time after he had spoken to Garrett, that “the British aircraft industry had made up its mind that Canada would not be allowed to build up a complete aircraft industry here that would be competitive with the British industry after the war.” Nonetheless, the construction of buildings and aerodromes for the air training program proceeded, along with the procurement of machine tools and equipment. And factories were erected or retooled to produce propellers, hydraulics, undercarriages and wheels. “In effect,” Kennedy adds, “an entire industry had to be built up.”

Bell and the aircraft branch had to deal with a continual stream of technical revisions; for instance, Canadian Car and Foundry Company of Montreal and Fairchild Aircraft Limited located nearby in Longueuil were compelled to make approximately 60,000 modifications ordered by American officials for the production of the Curtiss SB2C Helldiver, a speedy and effective dive bomber. Bell was most concerned by the length of time it might take for Canadian companies to deliver Avro Anson trainers desperately required for the air training program. In order to streamline and centralize production for the trainers, Bell recommended at the June meeting the creation of a Crown corporation called Federal Aircraft Limited. Based in Montreal, its chief objective was “to supervise and co-ordinate the necessary re-engineering and production of Anson parts and the final assembly of the aeroplanes.” As Howe, who wholeheartedly approved of the idea, later explained in the House of Commons, “Federal Aircraft is not a manufacturing company. It is a company that designs and supplies requirements, but the manufacturing is done by privately owned plants.” Bell’s proposal called for the company to be awarded a firm contract for 1,000 training aircraft to be delivered by August, and to be allowed a degree of independence in its operations. In theory, this was a good idea, yet the deadline set was unrealistic and proved impossible to meet given the technical problems involved in redesigning the planes using the American Jacobs engine. In addition, the RCAF had submitted major modifications with a change from a “hand to a hydraulically retracted undercarriage.” As a consequence, Federal Aircraft experienced about six months of difficulties, disputes, personality clashes and finger-pointing before the Ansons were manufactured.