Updating home wiring poses special challenges

More problematic than copper, and with rules that may be harder to navigate

Advertisement

Read this article for free:

or

Already have an account? Log in here »

To continue reading, please subscribe:

Monthly Digital Subscription

$0 for the first 4 weeks*

- Enjoy unlimited reading on winnipegfreepress.com

- Read the E-Edition, our digital replica newspaper

- Access News Break, our award-winning app

- Play interactive puzzles

*No charge for 4 weeks then price increases to the regular rate of $19.00 plus GST every four weeks. Offer available to new and qualified returning subscribers only. Cancel any time.

Monthly Digital Subscription

$4.75/week*

- Enjoy unlimited reading on winnipegfreepress.com

- Read the E-Edition, our digital replica newspaper

- Access News Break, our award-winning app

- Play interactive puzzles

*Billed as $19 plus GST every four weeks. Cancel any time.

To continue reading, please subscribe:

Add Free Press access to your Brandon Sun subscription for only an additional

$1 for the first 4 weeks*

*Your next subscription payment will increase by $1.00 and you will be charged $16.99 plus GST for four weeks. After four weeks, your payment will increase to $23.99 plus GST every four weeks.

Read unlimited articles for free today:

or

Already have an account? Log in here »

Hey there, time traveller!

This article was published 27/05/2017 (3099 days ago), so information in it may no longer be current.

Question: I was wondering what the approved methods are in Manitoba for updating devices in a home with aluminum wiring? My research took me to your response to a question in a previous article in the Winnipeg Free Press.

I want to verify that the use of CO/ALR-rated devices is, in fact, still acceptable and recommended. Also, in my research, it looks as though aluminum-rated wire connectors are not safe, even on aluminum conductors. I came across the AlumiConn connector by King Innovation. I get the impression that pig-tailing a copper conductor with an AlumiConn connector to standard CU-rated devices is much safer than pig-tailing with aluminum-rated wire connectors and is even preferable to using CO/ALR-rated devices with the original aluminum conductors. At least, it would seem that they would be the only safe option for newer light fixtures with CU-rated leads. I believe the AlumiConn connectors are cUL rated, according to a ratings website I checked earlier.

I would like your input on this issue given the availability of these AlumiConn connectors.

— Curtis Shupenia

Answer: You have raised an excellent point with your inquiry about safe and correct methods for upgrading electrical fixtures in homes with aluminum wiring. As with several topics, there may be widely diverging opinions on this issue. While I will give you my take, it is always best to consult directly with the municipal building inspection division in the area where you live for regional requirements, before starting upgrades.

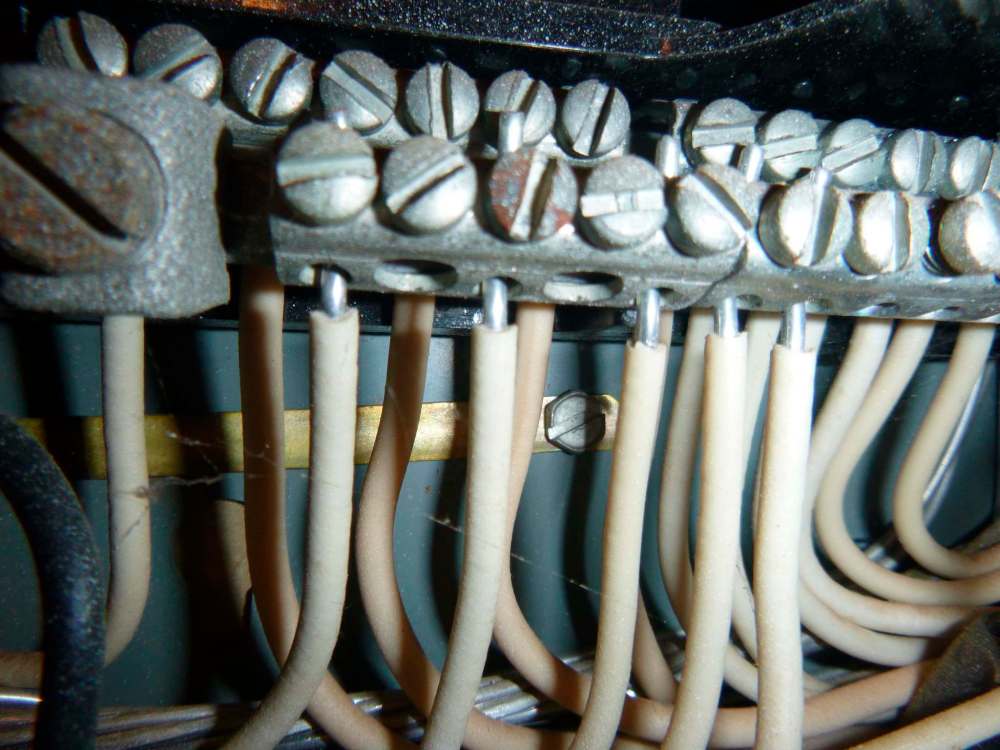

Aluminum wiring was used in Canadian homes in various locations from about the mid-1960s to the mid-1970s. If you have a home built in that timeframe, there is a high likelihood you have some aluminum conductors (wires) in the electrical distribution system. If your home was constructed toward the end of that period, it is more likely that you have properly rated receptacles or other devices suitable for safe use with aluminum wiring. If not, unless extensive upgrading has been done, you should look at upgrading for safety enhancement.

The problems with aluminum conductors in homes fall into a few different categories, all of which may affect homes with this system installed. The first issue is poor conduction of aluminum relative to copper. This problem has been mostly solved by requiring wiring one gauge larger than copper for all systems. You will notice standard aluminum wiring for most 15-amp circuits in your home is 12- rather than 14-gauge, common with copper. Larger conductors for higher amperage circuits should also be appropriately sized.

The second problem with this type of wiring is that is quite soft, which makes it more susceptible to damage. This damage can occur during installation or after the home is built. Cutting, bending and securing the wiring to electrical devices, which is necessary during installation, may create damage that would not normally affect stronger copper conductors. This feature, combined with incompatibility with various metals or alloys is where the danger comes from.

Wiring that is damaged, or builds up excessive corrosion, has the possibility of creating small gaps between itself and the receptacles, switches and other fixtures it connects to. These micro gaps can allow arcing to occur, which can lead to electrical fires. Also, crushed or crimped wires are more susceptible to breakage, due to expansion and contraction from overheating and cooling, further creating a serious fire safety threat. The initial receptacles and light switches used with this wiring were found to be incompatible, leading to overheating and fire hazards, mostly within junction boxes at duplex receptacles. Newer fixtures with the rating CO/ALR were developed that minimized this threat, but as you state, there can still be issues with these, sometimes due to sloppy installation techniques.

Pig-tailing involves using the existing receptacles and other devices, even if they are not properly rated for aluminum, provided they are not damaged. What this involves is splicing a short piece of copper wire to the existing aluminum, within the confines of a proper junction box, and then connecting the copper conductors to the electrical device. As you have noted, previously rated wire nut connectors were thought to be safe, but issues have arisen that call that thinking into question.

My eyes were opened to this issue recently when I met an electrical instructor from our local college who teaches electrical students and apprentices with the goal of becoming Red Seal-licensed electricians. He showed me one of only a few types of wire nut connectors he deemed to be safe for pig-tailing in existing buildings with aluminum wiring. His expert opinion was that regular connectors were not acceptable, even if properly used with non-conductive paste. Inclusion of that “grease,” as it is often called, is not only critical with the proper connectors, the method of installation is also important. Applying the paste to the wires before they are twisted together and before they are installed in the wire nut connectors is the correct method and the only one he would accept as safe. I am not sure if the connectors he showed me are the AlumiConn ones you site, but I suspect they would be one of the few types deemed appropriate.

As illustrated by my previously outdated information, checking with the local authorities before beginning a retrofit of the electrical devices in your home is paramount. They should be able to tell you what is currently deemed acceptable and safe in your location to properly guide you in doing the job properly. Alternatively, hiring a licensed electrician to do the task for you is never the wrong choice and should assure you of complete safety in relation to the aluminum wiring and connections in your home.

Ari Marantz is the owner of Trained Eye Home Inspection Ltd. and the past president of the Canadian Association of Home & Property Inspectors — Manitoba (cahpi.mb.ca). Questions can be emailed to the address below. Ari can be reached at 204-291-5358 or check out his website at trainedeye.ca.

trainedeye@iname.com